Motion

Concerning the movement of the Rover, we have mainly been focused on the mechanic, the motors, and the rocker bogie concept which allows us to control the rover’s trajectory and gear.

Table of content

Motors

We have taken a long time (about 3 months) to choose the continuous power motors and their controllers. We thank the robotics club POBOT, particularly Eric PASCUAL, for his useful advices because a motor is one of the most important component of the rover and it has been a very tricky choice.

We have chosen continuous power motors because servomotors are not designed for continuous rotation but rather for brief movements. We have also used the robotshop sizing tool which gives many characteristics as gear, torque, power of the motor in function of parameter like wheels' diameter, weight...

So, we have defined some important characteristics which correspond to the "Motoréducteur train droit 21W/750":

- gear of 2cm/s

- torque of 2Nm=20.3 kg/cm = 282 oz/pc

- rotation of 26,4 tr/min (or RPM) = 2.72 rad/s

- bearings must be strong to support the rover weight

The total weight amounts to 1.62kg (6 motors) and the control is carried out by 6 controllers 13A Cytron whose power varies between 5 to 30V (no need of heat sink). The rover need also 4 servo motors for the rotation with steel gears and 2 pivots which can support 50kg. On Curiosity these servos have a 360° rotation amplitude but we have chosen them with an amplitude of 180° because the motors have 2 directions (forward and reverse gear).

Main box

The real Martian rovers are built with honeycomb composite material which is very resistant. The satellites also use this component. It insulates the structure from freezing temperature thanks to an aerogel. We have had several choices for the main material:

- Steel: too heavy

- Aluminium: too expensive, difficult to curve, don’t authorize errors

- Plexiglas: too breakable (cracks)

- Plastic: not strong enough

- Wood: difficult to curve

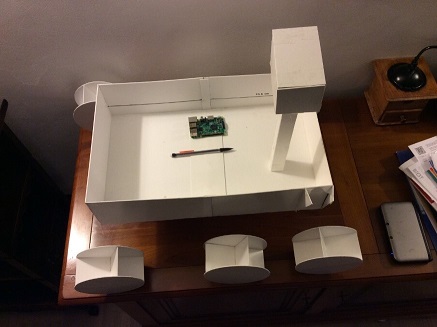

So, our first model in PVC (1.5mm then 4mm of thickness) has been based on some detailed examples on Internet and our own measurements directly on the computer with our own scale. It has allowed us to anticipate cutting and assembling problems. To build the trial version with a scale of 1:3 (0.53x0.53x0.5m) for an estimated weight of 15kg, we have defined a reference which was the wheel diameter of the rover. In fact, these dimensions allow us to put it in a boot.

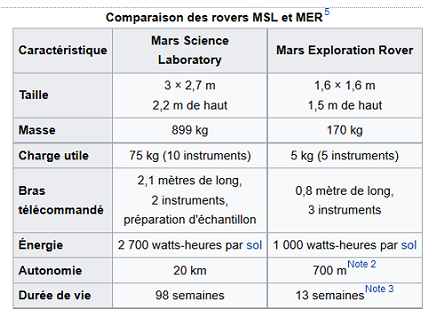

We have made many measurements on photos of Curiosity (MSL) and Opportunity (MER) and we have realized that the general shapes of the rovers were different. We have finally chosen Opportunity’s. Then, with the advices and help of SOFAB, particularly Marc FORNER, we built the main box made of wood pieces of 5mm thickness. For that, we have used the software LibreCad (thanks to the lesson taken with Jean DEMARTINI, member of the SOFAB) which allowed us to use the SOFAB laser cutter.

Rocker Bogie

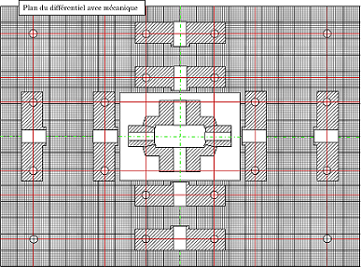

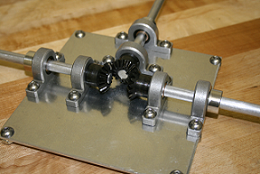

The rocker bogie system includes six wheels, six motors, four servo motors for the drive wheels and the differential. With this structure the rover has its six wheels in contact with the ground at all times even if it meets an obstacle so it won't get stuck in the Martian ground. On each side, 2 wheels over 3 are united. The differential by conical cogwheel is situated under the main box.

To understand this system and build it, we have had the help of a mechanic in Orange to whom we have supplied technical drawings of the differential.

We have had to choose many connection pieces like, for example, the connection between this structure and the wheels or ball bearings (KP08 and KFL08). By analogy with the box, we have based our construction on photos and we have built ourselves the aluminium legs and the articulations with a folding machine. Some parts have been very difficult to build because they were too breakable as the flat angle bracket on the wheels for example.

Head

Moreover, the head, sitting on a "mast", which contains a night camera and two other ones to create a 3D vision, has been designed. We also control the head with two movements (right/left and top/bottom) thanks to two servo motors so that it can have a large overview of the landmark and anticipate obstacles. In fact, 4 pairs of cameras will be put on and around the box to prevent from obstacles. Usually there are 3 servos: one more to fold up the head on the box but we won't carry out this functionality.

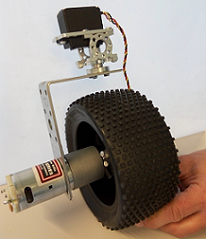

Tyres

We have chosen large tyres (Absima 2520013 with a diameter of 145mm) with stonemason’s pic for a better adhesion. Indeed, the dimension is directly connected with the obstacles size and a low pressure is an important factor to ensure the motion of the rover.

The next aim is to implement a motion control and give the possibility to recognize its landmark or create a path avoiding obstacles and dangers. To be autonomous, we have the ambition of creating an enslavement. We will program the motor and servo control on a STM32 in C/C++ because it needs lots of fast calculus and we will create a kind of costumer/server system between the raspberry and the STM32. Indeed, the STM32 will lead interruptions sent by the raspberry if some obstacles are detected. For that we have taken lessons with Jean DEMARTINI.